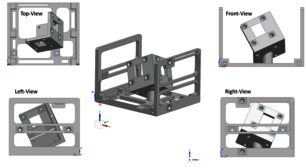

The structure has been Aluminium coated in order to improve electrical and thermal conductance. This coating is 3-5 microns thick and is applied to all the internal and external surfaces. The use of these polymeric materials together with the coating enables its usage in most space applications with the added advantage of around 40% mass reduction with regards to traditional CubeSat structures. The design has also taken into account manufacturing and assembly constraints in order to reduce also the manufacturing cost. The aim of this experiment is:

- Produce a prototype for a PEEK CubeSat by Additive Manufacturing.

- Comply with all requirements of these structures and improve performance as three advantages arise from AM utilization:

- Lightweight CubeSat structure for reducing cost and energy usage

- CubeSat payload capacity is increased

- Join assembly parts to manufacture as a unified structure reducing the assembly effort

- Implementation of metallization process for the rails and complying with roughness specification and ensuring the optimum interface between CubeSat and P-POD