SM3DPS

General Information

Start Date:

End Date:

2025

Status:

On-going

Programme:

–

Programme Reference:

The Objective

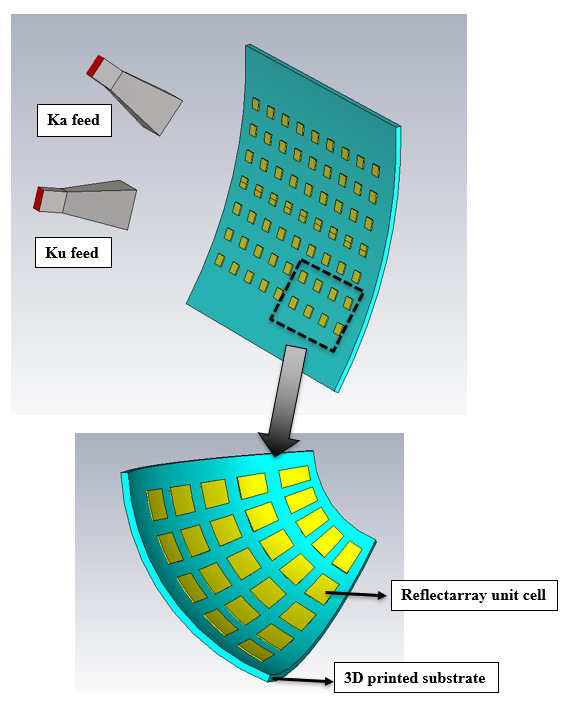

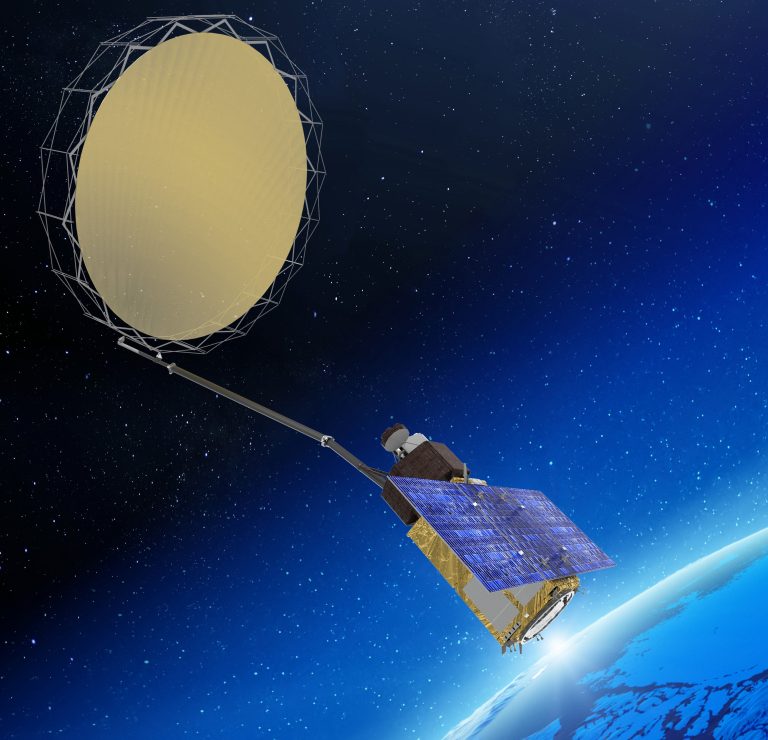

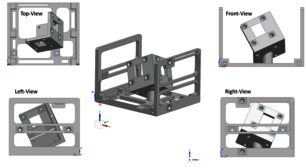

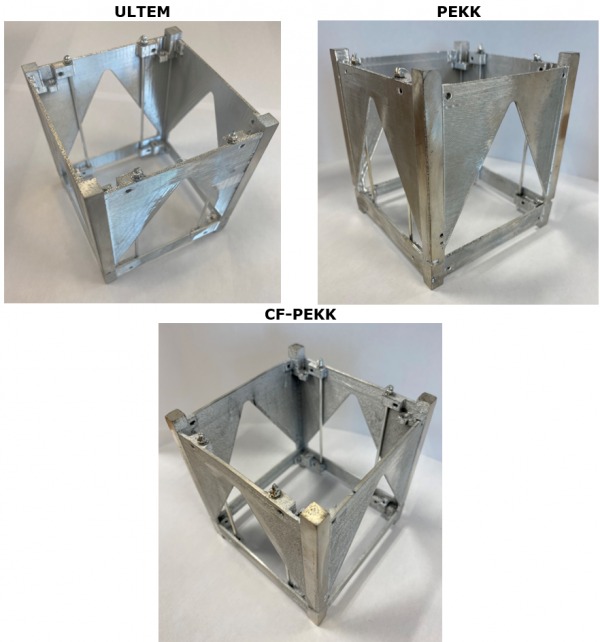

Selective Metallisation on 3D Printed Surfaces is a project that aims to develop a selective metallisation technique for use on (conformal) surfaces of 3D printed RF components. Demonstration shall be done on antenna and other RF component breadboards for ground and space use (target TRL is 4 – Component and/or breadboard functional verification in laboratory environment). Selective metallisation is the process where metal is deposited on specific areas of a substrate, while other areas are left uncoated. This technique has a wide range of applications in various industries, including electronics, automotive, aerospace and medical devices.

OHB Contributions

OHB Hellas is responsible for the trade-off and selection of different 3D printing design/analysis tools as well as for identifying spin-off opportunities and for proposing a route to the market for the SM3DPS process (roadmap).

Customer and Partners